Injection Moulding Process

Injection Machines

Plastic injection machines are utilised to hold the mould in position and to heat up the plastic so it melts as it is injected inside the mould cavity. Injection machine are normally classified by it's tonnage. The tonnage is the actual clamping force of the clamps used to hold the moulds during the injection process.Depending on the size and material used for the moulds can be anything up to 5000 tons.

Injection machine are normally classified by it's tonnage. The tonnage is the actual clamping force of the clamps used to hold the moulds during the injection process.Depending on the size and material used for the moulds can be anything up to 5000 tons.

Mould Tools

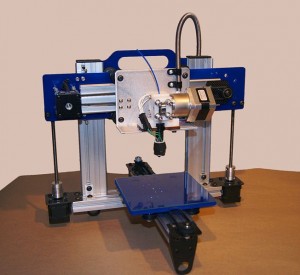

You will always get some sort of defects during the injection moulding process due to the properties of the materials the unique shape of the mould some of the most common defects are sink marks, weld lines, short mould,silver streak, flashes and flow marks. However with good mould tool design and experience of using the right materials a lot of these defects can be overcome. As in today's consumer driven market people are looking for good design and slick looking electronic gadgets in telecommunications and the automotive area. With new technology like 3d printing should help injection moulding designers produce more complicated and sleek designs in the future.

You will always get some sort of defects during the injection moulding process due to the properties of the materials the unique shape of the mould some of the most common defects are sink marks, weld lines, short mould,silver streak, flashes and flow marks. However with good mould tool design and experience of using the right materials a lot of these defects can be overcome. As in today's consumer driven market people are looking for good design and slick looking electronic gadgets in telecommunications and the automotive area. With new technology like 3d printing should help injection moulding designers produce more complicated and sleek designs in the future.

What is Injection Moulding was last modified: February 19th, 2014 by